A Declaration of Technological Independence: Advancing Toward the Global Stage Through Full Drone Localization

| VOLOLAND CEO - Sungho Ahn | ||

It is an era in which drones have grown far beyond a hobby or advanced technology; they have become a core asset across national security, industry, public services, and disaster response. And there is one company standing at the forefront of that transformation — Vololand Co., Ltd. (CEO Sungho Ahn).

Just five years after its establishment, Vololand has secured a unique and unrivaled position within South Korea’s drone industry, earning the title of the nation’s leading force in drone component localization. Reflecting on the company’s mission, CEO Sungho Ahn states, “The moment our drone helped save a life, every hardship instantly became worth it.”

In 2024, Vololand was selected as the top-performing company in the Ministry of Land, Infrastructure and Transport’s (MOLIT) national drone delivery program, earning the Minister’s Award. Continuing its momentum this year, Vololand is now taking a leading role in MOLIT’s Drone Commercialization Support Program, forming a consortium with multiple industry partners and spearheading the development and demonstration of core technologies as the principal organization.

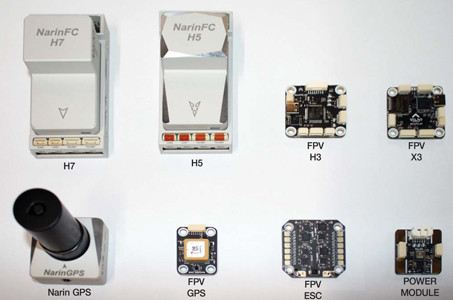

Particularly noteworthy is Vololand’s success in localizing key drone modules — ESCs, GPS units, and flight controllers — components that had long relied on foreign suppliers. In 2025, the company officially began domestic sales of these proprietary products, and its technologies are now being supplied to more than 20 Korean drone manufacturers, signaling a major leap toward full commercialization.

Recognized as a “First Penguin Company” by the Korea Credit Guarantee Fund, Vololand has distinguished itself through successful drone delivery operations to high-altitude regions such as Ganwoljae. These achievements serve as foundational data for operational manuals applicable to diverse terrains and environments both domestically and internationally, and are expected to have significant implications for future drone applications in military and disaster-response missions.

Vololand’s independently developed NarinFC flight controller is one of the few in South Korea to have been used in more than 1,000 real-world delivery missions, and is built entirely with Korean-manufactured components — without any Chinese or Taiwanese parts. Designed with the explicit goal of surpassing global competitors such as DJI, the NarinFC reflects the company’s concentrated investment in technological capability and structural design. Breaking away from reliance on Chinese components is one of Vololand’s most critical guiding principles. CEO Sungho Ahn emphasized, “The United States is moving in the same direction. What the world needs now is a company that possesses true self-reliance — a company capable of replacing Chinese components. That is exactly what we at Vololand are doing.”

Vololand continues to push forward with the localization of core drone components, with both design and manufacturing carried out entirely in South Korea. This is not merely technological independence, but a mission tied directly to securing industrial sovereignty.

The company is now accelerating the development of drone motors — the most expensive and critical component of the propulsion system — while simultaneously testing prototypes of an independent lithium battery system for drones. The core challenge is reducing weight while maintaining energy density, and to this end Vololand is pursuing strategic collaboration with domestic advanced-materials companies. Its in-house engineering team is directly designing battery-cell layouts and cooling systems, aiming to obtain certification within the year. In the motor field, Vololand is pursuing modular architecture, enabling flexible compatibility across a variety of aircraft platforms.

Breaking Free from Chinese Dependency: Opening the Future Through Drone Platform Innovation

Vololand has obtained three international quality management certifications — ISO 9001, 14001, and 45001 — and has also completed registration as an information and communications construction company. The company currently holds more than 20 patents, with additional domestic and international patents underway. Through collaboration with a major Korean logistics corporation, Vololand is building the foundation for the commercialization of drone delivery, while simultaneously accelerating the development of agricultural drones for entry into the U.S. market. The company plans to commercialize an agricultural drone made with 100% Korean-manufactured components by 2026, targeting both domestic and global markets. Beginning in 2025, Vololand will expand into in-house motor development, with a vision to complete full platform infrastructure — spanning space, facilities, and equipment — by 2026. A technology roadmap is already in motion to fully localize both motors and batteries, and the company is actively securing investment to support these initiatives.

Vololand possesses the full technological spectrum of drones — from components to complete aircraft and drone stations. The company is advancing a wide range of drone-station technologies, including automatic charging with precision takeoff and landing, battery-swap stations for uninterrupted deployment, and unmanned pickup systems with user authentication. Vololand is also expanding into diverse application areas such as mountain rescue, disaster monitoring, and logistics transportation through systems like tower-type multi-station platforms. All of these technologies demonstrate competitiveness that exceeds that of existing commercial systems, and Vololand has set a firm goal not merely to follow DJI, but to surpass it through superior technological capability.

As drones emerge as the core of future transportation and logistics, Vololand is evolving beyond a simple manufacturing company to become a comprehensive drone-industry platform provider, spanning both hardware and software. By 2026, the company aims to complete high-performance drone products specifically designed for the U.S. agricultural market and expand globally on the basis of its competitive technology. Throughout this process, Vololand’s strategy is clear: the United States is the primary target market, and the company has already secured the level of performance and quality necessary to compete head-to-head in terms of both cost and technological excellence.

To strengthen its global expansion, Vololand is currently pursuing partnerships with agricultural equipment distributors in the United States and plans to commercialize at least three agricultural drone models optimized for local farming environments by 2026. The drones under development are preparing for U.S. regulatory certifications, and each component is undergoing military-grade reliability validation. In the mid- to long-term, Vololand aims to expand export channels beyond North America to Europe and Southeast Asian countries with large agricultural markets, and is simultaneously developing its own cloud-based integrated drone control platform to support global operations.

CEO Sungho Ahn also emphasized the importance of continued government demo and validation programs. “Just as national funding is provided for public transportation systems such as subways and buses, drone delivery must not end with pilot programs — it must continue steadily through commercialization,” he said. Ahn added that even if profitability remains low in the current stage, the industry must be driven by responsibility and persistence, and that only with continued attention and investment from local governments and the central government can the drone industry solidify its position as a critical national sector.

Vololand is not merely a commercial company — it is the driving engine behind the self-reliance and advancement of the drone industry. With a core identity as “the leader of drone component localization”, the company maintains an uncompromising commitment to outperform competitors in technology, quality, and pricing, and continues to accelerate its global push by building strong collaboration networks with specialized industry partners across multiple sectors.

<Interview with Sungho Ahn, CEO of Vololand Co., Ltd.>

Q. What is your definition of drones, and what goal do you pursue through them?

A. If I were to describe drones in one word, it would be “passion.” A drone is a composite of many different technologies, and its design is the core of everything. At Vololand, we don’t simply assemble components — we design and manufacture everything directly in Korea. Building this system is localization, and ultimately, the foundation of an independent industrial ecosystem. Our goal is not to follow, but to lead through technology.

Q. Why is the localization of drone components so important?

A. Until now, many companies have depended on motors, batteries, flight controllers, sensors, and chips sourced from Taiwan or China. However, considering national security and supply chain stability, localization is essential. Starting this year, all major Vololand drones are equipped with our own in-house flight controller, and we plan to export it to the United States as well. True self-reliance is achieved only when every component is designed and built with our own hands. We are deeply grateful to the Ministry of Land, Infrastructure and Transport and the Korea Institute of Aviation Safety Technology for establishing national policies and providing strong support for localization.

Q. What are the biggest challenges and goals for Vololand moving forward?

A. By 2026, we aim to fully commercialize our FPV drones and agricultural drones and make a full-scale entry into the United States. At the same time, we will complete the localization of batteries and motors, while enhancing the perfection of our station-based drone delivery system. And the transition to a platform-based business is essential. We are determined to evolve from a simple mechanical component manufacturer into a total drone solution company — internalizing everything from hardware to software. That is our vision.